Vendor Portal- MC

Client: Monte Carlo

Monte Carlo Fashion Ltd. (MCFL) is a leading Indian apparel brand known for its mid-premium cotton and woolen garments. The company offers a wide range of products and accessories under multiple sub-brands. Its presence spans 350+ exclusive brand outlets, 2,500+ multi-brand outlets, and major e-commerce platforms, making it one of India’s most recognized fashion retailers.

With manufacturing units in Ludhiana and a robust technology backbone—including SAP HANA and SAP Analytics Cloud—MCFL continues to optimize supply chain efficiency and scale its omnichannel retail presence. As of the latest reports, the company generates over ₹1,100 crore (approx. $130 million USD) in annual revenue, reflecting its strong market footprint and consistent growth trajectory.

With a complex network of vendors and high-volume production cycles, faced increasing challenges in managing purchase orders, production progress, and vendor coordination across multiple geographies. Fragmented processes, delayed updates, and manual tracking of production activities frequently resulted in bottlenecks, reduced visibility, and inefficiencies that hindered time-to-market and compromised supplier accountability.

To solve this, our team developed a custom-built Vendor Portal—a comprehensive web-based platform that digitizes and integrates the full spectrum of MCFL’s vendor collaboration and production monitoring processes.

Mission Statement

Our mission is to modernize supply chain collaboration by replacing fragmented, manual vendor coordination with a smart, connected digital ecosystem.

Through our vendor portal solution, we enable brands like Monte Carlo to gain real-time visibility, streamline purchase orders, track daily production progress, accelerate multi-level approvals, and centralize all critical documentation. The result is faster execution, stronger vendor accountability, and a supply chain that’s agile, transparent, and built for scale.

The Challenge:

1. Fragmented Communication Across Stakeholders

Vendor communication often happens across emails, calls, spreadsheets, and scattered documents, resulting in misalignment, missed updates, and long follow-up cycles.

👉 Outcome: Delays in approvals, misinterpretation of requirements, and friction in day-to-day coordination.

2. Manual Production Tracking & Reporting

Without a centralized system, vendors are forced to submit production updates via Excel or email, making it hard to maintain consistency or validate progress.

👉 Outcome: Lack of real-time visibility, duplicated efforts, and last-minute surprises in production timelines.

3. Delayed and Inaccurate Shipment Planning

Advance Shipment Notifications (ASNs) and logistics planning are manual, disconnected, and prone to errors.

👉 Outcome: Poor inventory forecasting, missed deliveries, and operational inefficiencies at receiving warehouses.

4. No Single Source of Truth for Documentation

Documents like POs, invoices, size sets, and approval records are often scattered or siloed.

👉 Outcome: Difficulty tracking audit trails, increased risk of errors, and wasted time retrieving records during inspections or disputes.

5. Inefficient Approval Workflows

Multi-step approvals (e.g., for ASNs or size set approvals) are often managed manually or through informal channels.

👉 Outcome: Bottlenecks in production cycles, dependency on key personnel, and no visibility into status for vendors.

6. Limited Visibility into Daily Operations

Brands have little insight into what’s happening on the vendor floor—whether garments are being cut, stitched, or packed.

👉 Outcome: Inability to plan downstream processes like distribution, marketing, or replenishment accurately.

7. Lack of Standardized Reporting and Analytics

Without digital systems, vendors report data in inconsistent formats, making analysis and performance tracking unreliable.

👉 Outcome: No clear KPIs, no vendor benchmarking, and poor supply chain decisions.

Our Solution

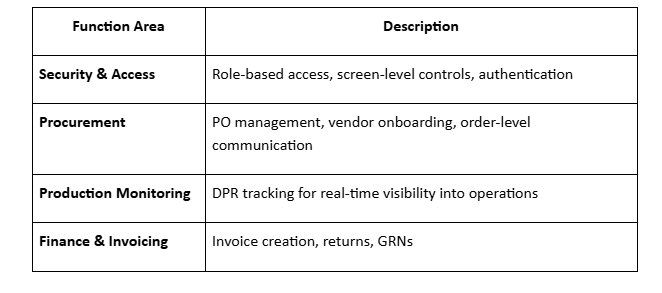

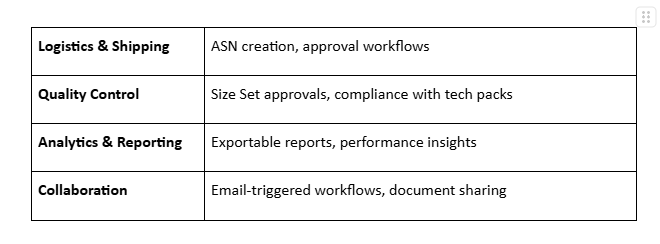

Summary of Core Business Functions Tackled:

WHAT WE DELIVERED:

Key Functional Modules & Capabilities [in dropdown style]

1. User Role Management (Admin Panel)

- Role-based access for Admin, Vendor, and MCFL users.

- Admin can create, block, delete, and reset users with ease.

- Email & screen-based access controls to specific portal functionalities like ASN approval and DPR screens.

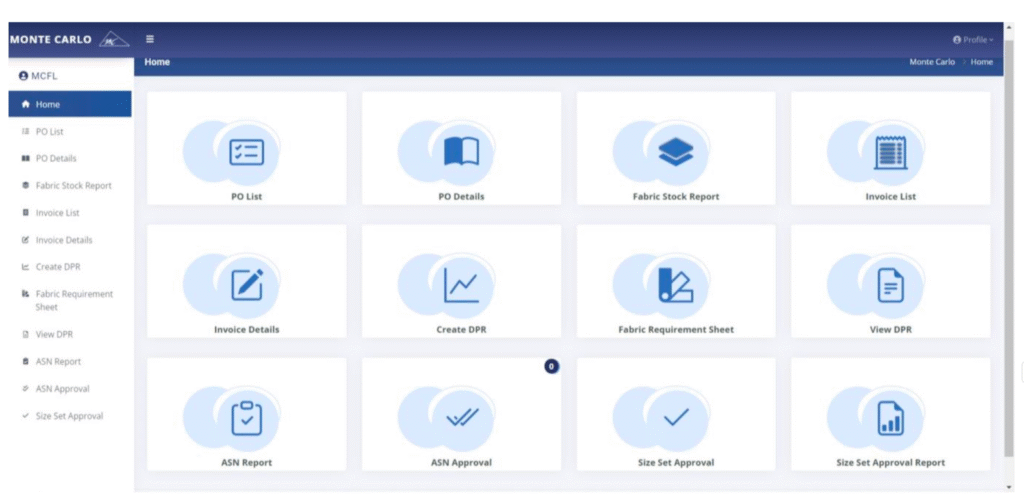

2. Vendor Dashboard & Operations

- Real-time dashboard with navigation tiles for fast access.

- Vendors can:

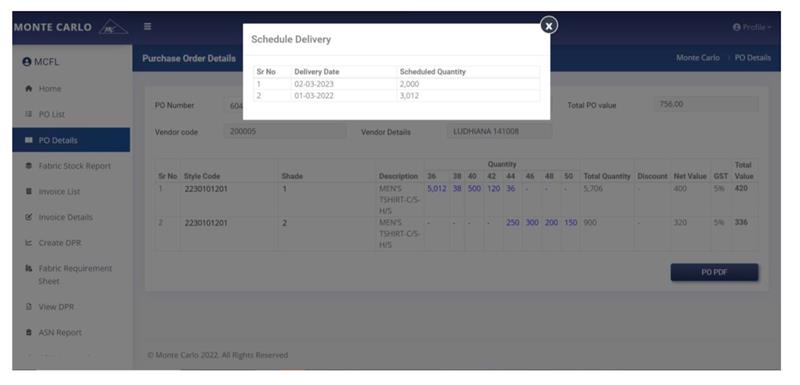

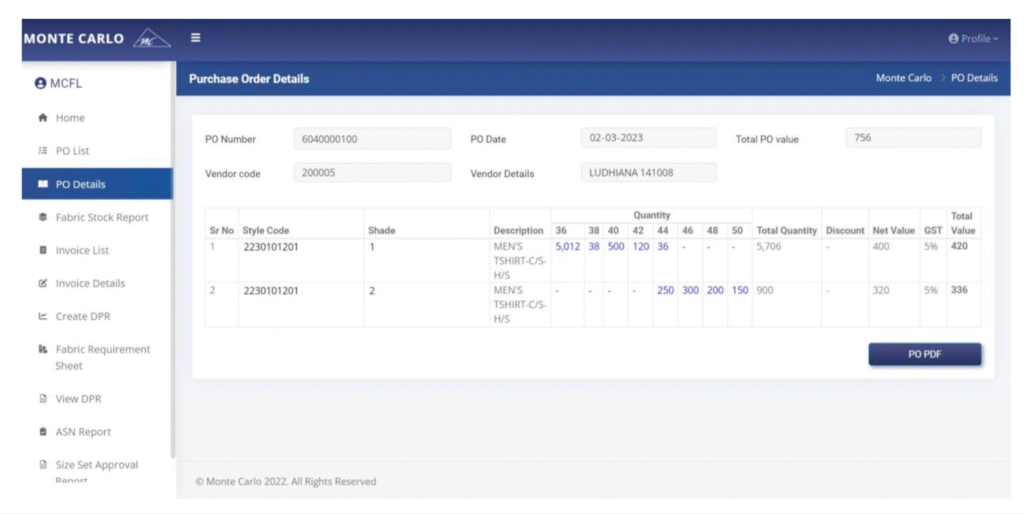

- View and manage Purchase Orders (POs)

- Submit Daily Progress Reports (DPR)

- Generate Invoices, view fabric stock, and manage returns.

- Create and send Advanced Shipment Notifications (ASN).

- Upload and manage Size Set documents and track their approval.

- View and manage Purchase Orders (POs)

3. Monte Carlo (MCFL) User Dashboard

- MCFL users can:

- View all vendor activities.

- Review and approve/reject DPRs, ASNs, and Size Sets.

- Download supporting documents and filter reports.

- Maintain an audit trail of vendor compliance and production flow.

- View all vendor activities.

4. Data & Document Management

- Exportable reports in PDF and Excel for DPR, Size Set, ASN.

- Upload/track supporting documents for tech packs, shipments, and approvals.

- Email integration for document dispatch (e.g., sending PO/Invoice PDFs).

5. Detailed Production Visibility

- DPR module captures granular data on stages like cutting, stitching, printing, etc.

- Size-wise fabric tracking and approvals for quality compliance.

- Filterable reports help identify bottlenecks or delays at any stage.

What is a DPR?

A Daily Progress Report is a digital log submitted by vendors to track and update the status of daily production activities against purchase orders (POs). It enables real-time visibility into manufacturing operations for the buyer (in this case, a company like Monte Carlo Fashion Ltd.).

Key Functions of DPR in a Vendor Portal:

- Tracks Production Milestones

– Vendors report progress on activities like cutting, stitching, printing, finishing, and packing. - Tied to Specific POs and Dates

– DPR entries are linked to specific Purchase Orders and line items, with timestamped updates. - Upload Support Documents

– Vendors can attach supporting files such as images, size sets, or QC sheets. - Enables Buyer Visibility

– Brands like MCFL can view cumulative production progress across vendors, download reports, and compare actuals vs. expected timelines. - Integrated with Approvals

– DPR submission may be locked until a Size Set is approved or until a Tech Pack is received. - Helps in Delay Management – Any delay in production can be flagged and mitigated quickly, reducing last-minute surprises.

Example:

If a vendor is producing 5,000 shirts, the DPR will log daily how many units are cut, stitched, and packed—enabling MCFL to plan shipments, manage inventory, and align store rollouts accordingly.